Beginning at 9.45am on Friday 17 May, the Eton College Design Schools hosted Dyson Design Day. Pupils from Holyport College and Slough & Eton School were invited to partake in an action-packed day of discussing, designing and prototyping. All pupils were split into groups containing roughly two pupils from each of the respective schools before being given a very open-ended brief with the end goal of creating a model of the product of their choice. After a quick safety briefing, the Design Schools rapidly descended into a frenzy of cardboard, hot glue and masking tape. By the end of the day, the pupils had created six impressive prototypes alongside a product pitch explaining the purpose of their product and answering increasingly difficult questions.

Engineers from Dyson were invited to Eton to present the brief to the pupils and evaluate their products after the pitch. The surprising yet fitting brief of ‘Create something that solves an everyday problem using air’ was entrusted to the pupils, giving them enormous freedom to design almost anything. The groups were divided up and split across two rooms, with 15 minutes to discuss and sketch potential ideas. After quickly overcoming the creative inertia, the groups were able to choose a product they wished to develop.

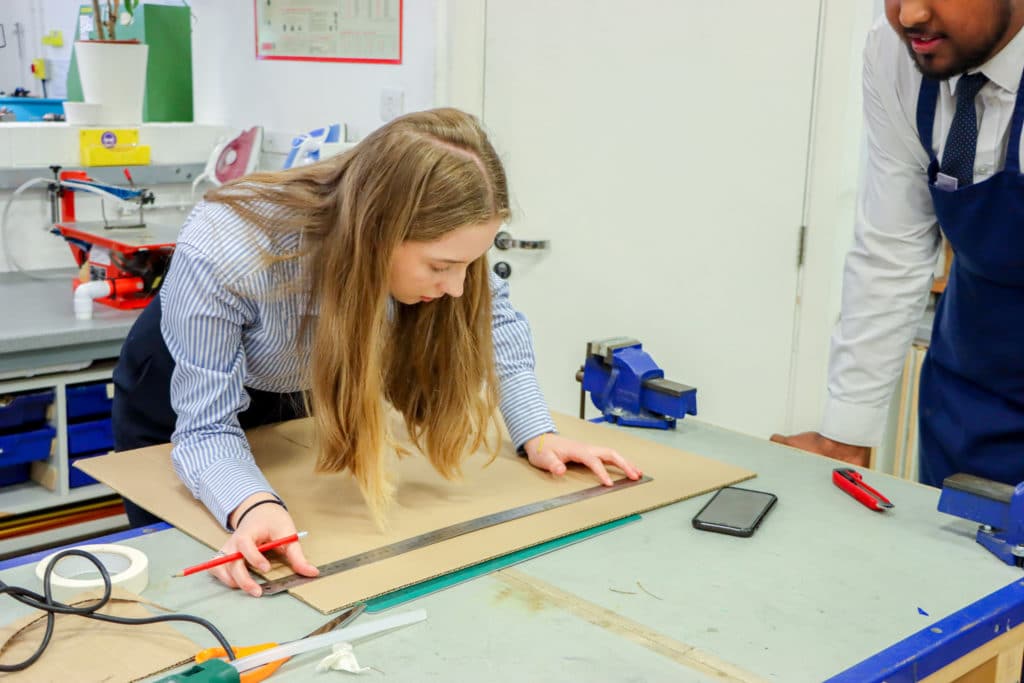

The groups were escorted downstairs and broken between the engineering and multimedia workshops to be provided with a vast array of prototyping tools and materials including components of dissembled Dyson products. They immediately assembled their arsenal of cutting boards and knives and got to work.

The teams of pupils were able to come together and labour with astounding efficiency in order to create their prototypes in the short time-frame provided. From the tornado of uniform and crafting materials emerged six successful prototypes, each defining the purpose and function of the hypothetical final product. In the true spirit of Dyson’s 5,127 prototypes, the first produced by the pupils were not flawless; however, they still offered an impressive taste of how a final version may work.

The six products designed were:

- A wardrobe that could dry and iron the clothes hung within it

- A bladeless fan-powered car with self-charging lithium batteries

- An automatic umbrella dryer to be placed at the entrances of buildings

- A swivelling battery-powered fan to be stored in a pocket on hot days

- An automatic person dryer to be placed outside of a shower

- A mood-setting device that could release scents as well as play music and change colour

The pupils took a packed lunch to be swiftly eaten in the colonnade outside the Design Schools while the Dyson engineers evaluated the products. Each product was given various criticisms and praises based on the prototype and overall idea. Finally, each engineer selected a product they considered to be the best. The self-ironing wardrobe was selected as a winner based on its success as a prototype. The group had created a sliding two-axis system using string so that the ironing arm could slip between the vinyl-covered cardboard clothes. The other winner selected was the umbrella dryer by virtue of its very realistic function as a product and high chance of success in the real world. The day was concluded at 2.45pm after the product ‘grading’, with the students satisfied by their display of abilities.